Ming Xuan Gan

Nanyang Technological University, Singapore

Title: Consistency of 3D printing spodumene articles

Biography

Biography: Ming Xuan Gan

Abstract

Statement of the Problem: Two of the many issues in selective laser melting is the repeatability and consistency of the printed parts. In particular, the properties of the printed parts may vary with respect to the printing locations on the substrate plate. Moreover, part property variation can also occur between separate print jobs. Therefore, this study aims to study the part properties at different locations of the substrate plate.

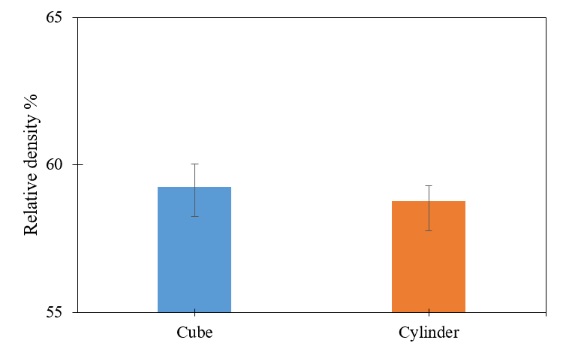

Methodology & Theoretical Orientation: We used selective laser melting to additive manufacture of 10 mm ×10 mm×10 mm cubic spodumene glass-ceramic articles. The relative density of these parts is then measured using the Archimedes method and tabulated. On a separate print job, cylinders of Ø12 mm × 12 mm were printed. As a rule of thumb, the relative density of these samples should be independent of geometry in order to prove the consistency of printing this material.

Findings: On average, the relative density of all the cubic samples was measured to be 59.231% with a standard deviation of 0.98%. Based on this average, the difference in relative densities at different locations was found to be less than 1%. The largest difference in relative density was calculated to be 3.98% at two different locations. Nevertheless, this shows that the relative densities of these parts printed at different locations were relatively consistent. Cylindrical samples printed were also measured to have very similar relative densities with the cubes.

Conclusion & Significance: In conclusion, with the correct set-up and processing conditions, glass-ceramic parts can be printed with considerable consistency in terms of relative density. This study also shows the consistency for two different geometries as both produced comparatively similar relative densities.

Figure.1: Comparison of relative density between cubic and cylindrical samples.

Recent Publications :

- C H Wong and M X Gan (2016) Selective laser melting of spodumene: An exploratory study, 2nd International Conference on Progress in Additive Manufacturing, Singapore,16 May 2016 – 19 May 2016

- M. X. Gan and C. H. Wong, “Effect of hatch spacing on the density of selectively laser melted spodumene,” 6th International Congress on Ceramics, Dresden, Germany, 21 August 2016 – 25 August 2016.

- C H Wong and M X Gan (2016) Practical support structures for selective laser melting. Journal of Materials Processing Technology 238: 474-484.

Speaker Presentations

Speaker PPTs Click Here